I have gone to different incubator manufacturers to make my YouTube channel videos. As a result, many incubator machine sellers have been introduced who make good profits by making their own egg incubator machine and selling them.

I also had some curiosity about this incubator machine. A few days ago, I bought the equipment and made a 100-capacity incubator machine for hobby purposes. I used this machine to hatch Sonali chicken eggs. Then I got about 100% hatching results.

Therefore, in this article, I will share my experience and provide detailed information about the process of making this incubator machine, its operation, and its profit margin.

What Is Incubator Machine:

The incubator machine is a machine that hatches eggs. This machine hatched duck eggs, chicken eggs, and bird eggs using scientific techniques. The temperature, humidity, and eggs turn automatically in this machine.

Type Of Incubator Machine:

Egg incubator machine are mainly three type-

- Automatic Incubator Machine

- Semi-automatic Incubator machine

- Manual Incubator machine

Automatic Incubator Machine:

Automatic incubator machines are mainly used for commercial purposes. This machine has a capacity of 500 to 100,000 eggs. An automatic incubator machine mainly turns eggs periodically and also automatically controls temperature and humidity. Turns are set basically every 2 hours duration .

This automatic incubator machine has a price range in India of Rs 60000–300000, depending on its capacity.

Advantage of Automatic Incubator Machine:

Automatic incubators are most popular nowadays because of some of the benefits of this type of machine. The some advantage of this machine are-

- This type of machine controls temperature and humidity automatically.

- It also turns eggs periodically according to a set time.

- This type of machine is user-friendly. It’s easy to use.

- Automatic incubator machines control temperature, humidity, and turn eggs automatically, but if the power shuts down or there is any problem, the alarm rings automatically.

- The automatic incubator machine is safer and more reliable.

The disadvantages of an automatic incubator machine are more expensive and its use only for commercial purposes.

Semi- automatic Incubator Machine :

Semi-automatic machines are mainly used on small and large farms. In this type of machine, the temperature and humidity are controlled by the controller, but the egg turning is done by hand. The capacity of this machine is 500–2000 eggs. This type of machine is not more expensive, so most small farmers use it for egg hatching.

Advantages of Semi- Automatic Incubator Machine:

Some advantage of semi-automatic incubator machine are:

- Semi-automatic machines are less expensive than full-automatic machines.

- This type of machine is budget-friendly. So many farmers can buy it for hatching eggs.

- In this machine, eggs are turned manually, so the chance of egg damage is very low.

- This type of machine is also user-friendly and easy to use.

The main disadvantage of a semi-automatic machine is the eggs have to be turned4 -5 times per day according to the fixed time, so it becomes very difficult to maintain the time.

Manual Incubator Machine:

A manual incubator machine is a type of incubator that is manually controlled temperature, humidity and egg turning. This machine temperature is controlled with the help of Kerosene Lantern. A container of water is placed inside the machine to control humidity. These machine eggs are turned by hand 4-5 times daily.

The size of this machine is not very big, the capacity of this machine is 50-100 eggs. It is mostly used for domestic and hobby purposes. Any farmer should initially use manual incubators rather than commercial incubators as it provides basic understanding of hatching.

Manual Hatching

Advantage of Manual Incubator Machine:

Some advantage of manual incubator machine are:

- It is a very cheap machine which can be easily bought.

- This machine does not run on electricity so there is no cost on the electricity bill.

- This machine is very useful for basic understanding of hatching.

- It is very easy to use

The main disadvantage of this machine is that it is completely controlled manually, so it is very difficult to manage time and all the work has to be done by himself, so a lot of time is wasted.

Incubator Machine Making Process:

Here I will talk about making a small machine of 100 capacity which can be used for domestic or hobby purposes. It can be considered as a semi-automatic machine.

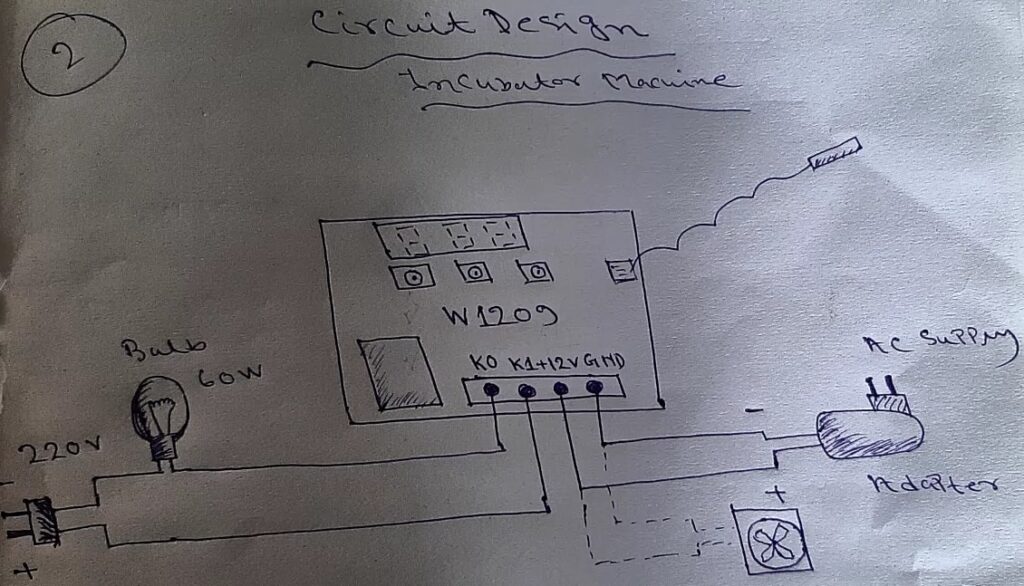

Component:

| Name of Component | Quantity of Component |

| Thermocol Box or Plastic Box | 1 |

| W 1209 Controller | 1 |

| 12 Volt AC-DC Adapter | 1 |

| Cooling Fan | 1 |

| Filament Bulb 60 watt | 1 |

| Bulb Holder | 1 |

| HTC Meter | 1 |

| Water Pot | 1 |

| Wire | Some |

Incubator Machine Making Process:

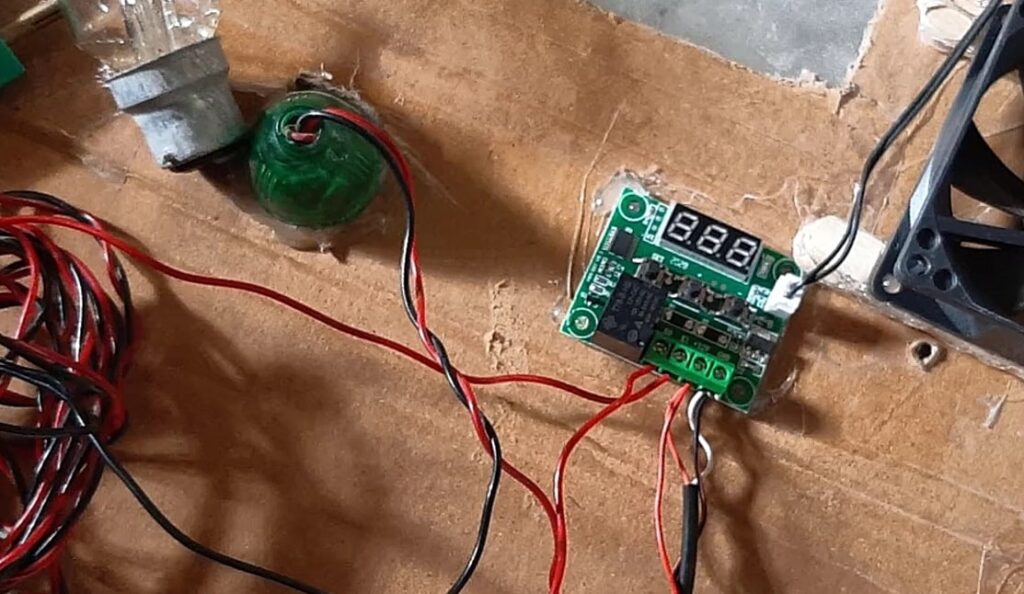

- At first, all the components must be collected and kept in one place.

- Then small holes should be made in the thermocouple box, and the 60-watt filament bulb should be well connected with the holder.

- Then connect the cooling fan and adapter to points GND and 12 volts of the W1209 controller.

- Now connect the 60 watt bulb and 220-volt plug to points A0 and A1 of the controller.

- Once everything is connected, the components should be well attached to the thermocouple box with glue.

- Now that the incubator machine is ready, take a small container of water and place it under the bulb. Rice husk should be spread inside the box to protect the eggs.

Also Read :How to Start Moringa Farming – A Complete Guide to Success

Controller Setting Formula:

Controller setting is the most important to getting good results from the incubator machine. First, press the “SET” button and hold it for a while. When the display of the controller starts blinking, press the ” + “and ” – ” buttons and set as per the formula given below.

| SET | Press “+” or “-“ |

| P0 | H |

| P1 | 0.5 |

| P2 | 110 |

| P3 | -50 |

| P4 | 00 |

| P5 | 00 |

| P6 | OFF |

Incubator Machine 100% Hatching Result Formula:

100% results can be obtained in the case of chicken eggs if they are properly maintained after put the eggs in the incubator machine.

Humidity:

- The humidity should be kept at 50-55% for the first 7 days of put eggs in the incubator machine.

- From 7 – 14 days, the humidity should be increased by 5% and to 55-60%.

- Then 14–18 days, humidity should be increased by 5% and kept at 60-65%.

- After 18 days, the eggs will be ready to hatch. During this time, the humidity should be kept at 70-80%. At this time, one should be very careful about the humidity to see that it does not become too low or too high.

Temperature:

The perfect temperature for hatching eggs in the machine is 37.7 degrees Celsius. But it will be harmful for hatching if the temperature is less than 35 degrees Celsius and more than 39 degrees Celsius.

Eggs Turn:

Egg turning is essential for hatching. To get good results it is necessary to turn 4-5 times daily.

Incubator Machine Making Business :

I have given all the information from my experience with the incubator machine. The formula is the same no matter what capacity machine you build. If you think you can make and sell these machines, In this way, you can earn a good amount of profit.

Again, you can make a machine and sell chickens or ducklings by hatching eggs. You can earn a good amount of profit in this business as well.